The Digital "Bat Scanner"

Detector

.

|

This project has come

to an end. Several key components were either

discontinued, or about to be discontinued. So, after a

run of about 6 years, we decided to close this project,

and concentrate our efforts on some of the newer projects

we have going. Check out the ArduBat project, and the Simple Bat

Detector.

In order to provide

continuing support for those who have built the Bat

Scanner, we are keeping this archived information

available here.

I am still happy to

answer questions and offer assistance to anyone who has

built this kit. I can even supply some replacement parts

... but not circuit boards. Just email

me.

|

The key idea behind the scanning heterodyne bat

detector was to use a 16F628A PIC microprocessor to generate the

mixing frequency for an otherwise standard heterodyne detecting

circuit. The program that was developed allowed the PIC to enable

the heterodyne detector to scan frequencies between any two

predefined decades, from 10kHz to 80kHz, in 2 kHz steps. It was

also possible to turn off the scanning and manually set the

frequency if desired. The PIC also provides the detector with a

digital LED display of the frequency that the detector is tuned

to.

But there was still one more feature to be

added ... a special detection circuit to let the PIC determine

when there was a sound. This made it possible to automatically

stop or pause the scanning when a sound was detected ... pretty

cool :-)

Here is a simplified block diagram of the

scanning heterodyne detector:

An electret microphone signal is

fed to a two transistor preamplifier which selectively amplifies

the frequencies in the ultrasound range. The preamplified

ultrasound is fed to an NE612 mixer IC that converts the

ultrasound to audible sound, using the reference frequency from

the PIC processor. The audible sound is fed to an LM-386

amplifier IC and speaker, as well as back to the PIC so that it

can detect when sound is present to pause or stop scanning. Three

buttons on the PIC processor allow selection of the tuned

frequency, as well as enabling the scanning mode and allowing the

setting of various operating parameters.

|

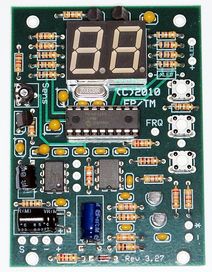

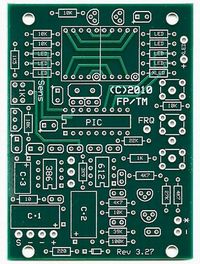

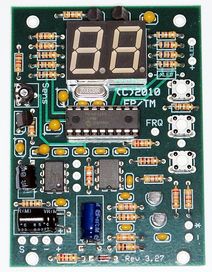

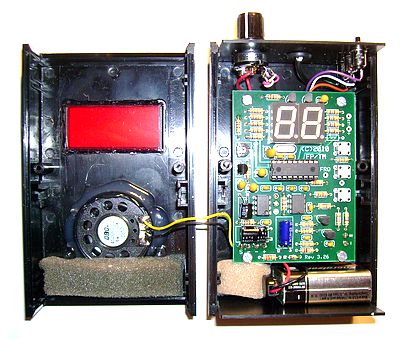

Frank worked on the code for the PIC

and made up the first prototypes ... and with a little

tweaking they worked well. My

job was to design the circuit board, and put some final

tweaks to the circuitry. We ended up with a 4 layer

circuit board. The board has heavy traces, a split power

plane, ground plane, solder masking on both sides, and a

very readable silk-screened parts layout.

We, and others, have successfully

constructed many Bat Scanner detectors over the

length of the project.

|

|

The idea of a scanning heterodyne wasn't really

new. There have been a couple of expensive commercial detectors

that have had scanning features. But this detector was relatively

low in cost, less than $100 to build, and has a very efficient

design.

Notes

on Maintenance ...

Circuit board repairs require a decent

temperature controlled soldering iron with a small chisel

or conical tip. Good lighting, and a magnifying glass are

essential for working with some of the small parts. You

also need to be mindful of ESD precautions when handling

the semi-conductors - especially the PIC microprocessor

chip.

All of the original construction

manuals for the Bat Scanner are still online.

The firmware HEX

file for the PIC processor is also here. If you need a

new 16F628A PIC for your Bat Scanner, and don't

have a PIC programmer, email me about getting

a replacement.

|

|

Tony Messina - Las Vegas, Nevada

- email: T-Rex@ix.netcom.com